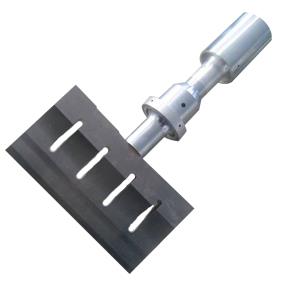

Ultrasonic cutter

Ultrasonic cutting technology uses the energy of sound waves to cut. It does not require sharp edges, nor does it require a lot of pressure, and it will not cause edge collapse and cut material damage. The ultrasonic cutting machine can easily cut resin, rubber and non-woven fabrics, films, various overlapping composite materials and food.

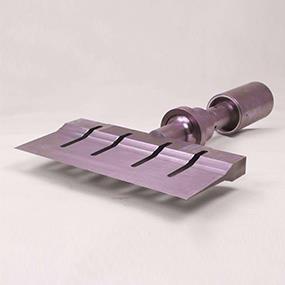

When it comes to cutting, there must be a knife on the ultrasonic cutting machine. Although it is also used as a knife, the one used hereUltrasonic cutterIt is very different from the knives we usually see.

Ultrasonic cutting is the use of ultrasonic energy to locally heat and melt the cut material. The principle of ultrasonic cutting knife is completely different from traditional pressure cutting. Due to the ultrasonic vibration of the cutting blade, the friction resistance is very small, and the cutting material is not easy to stick to the blade. Viscous and elastic materials, frozen materials such as food, rubber, etc., or objects that are inconvenient to cut under pressure are particularly effective. Ultrasonic cutting also has a great advantage, that is, while cutting, the cutting part has a fusion effect. The cutting part adopts edge banding treatment to prevent the cutting material (such as textile material flash) from being loose.

Ultrasonic cutting loads ultrasonic waves on the cutting tool, so that the cutting tool generates ultrasonic vibration, so as to achieve the cutting effect.

This cutting method is suitable for: raw rubber cutting, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit board cutting, natural fiber cutting, synthetic fiber deep digging, plastic shell processing, synthetic resin (including paint), handheld cutting, etc. .

Advantages of ultrasonic cutting knife:

1. There are many materials that can be cut, and the limitations are small.

2. High cutting precision, no rubber deformation.

3. Good cutting surface finish and good bonding performance.

4. Easy to apply to automated production.

5. Fast speed, high efficiency and low pollution.